Salt Medical specialises in precision extrusions for medical devices, producing high-quality catheter extrusions, multi-lumen tubing, and custom profiles for minimally invasive applications. Using advanced materials and processes, we deliver durable, flexible, biocompatible components that drive innovation and improve patient outcomes.

At Salt Medical, we specialize in precision thermoplastic extrusion to support the most demanding medical device applications. Our advanced extrusion processes enable the creation of complex tubing designs with exceptional dimensional control and consistency.

We work with a wide range of medical-grade materials—including PEEK, PEBAX®, polyurethane, nylon, and polycarbonate—to produce tubing with inner diameters as small as 0.2 mm and outer diameters up to 20 mm, maintaining tight tolerances down to ±0.0065 mm.

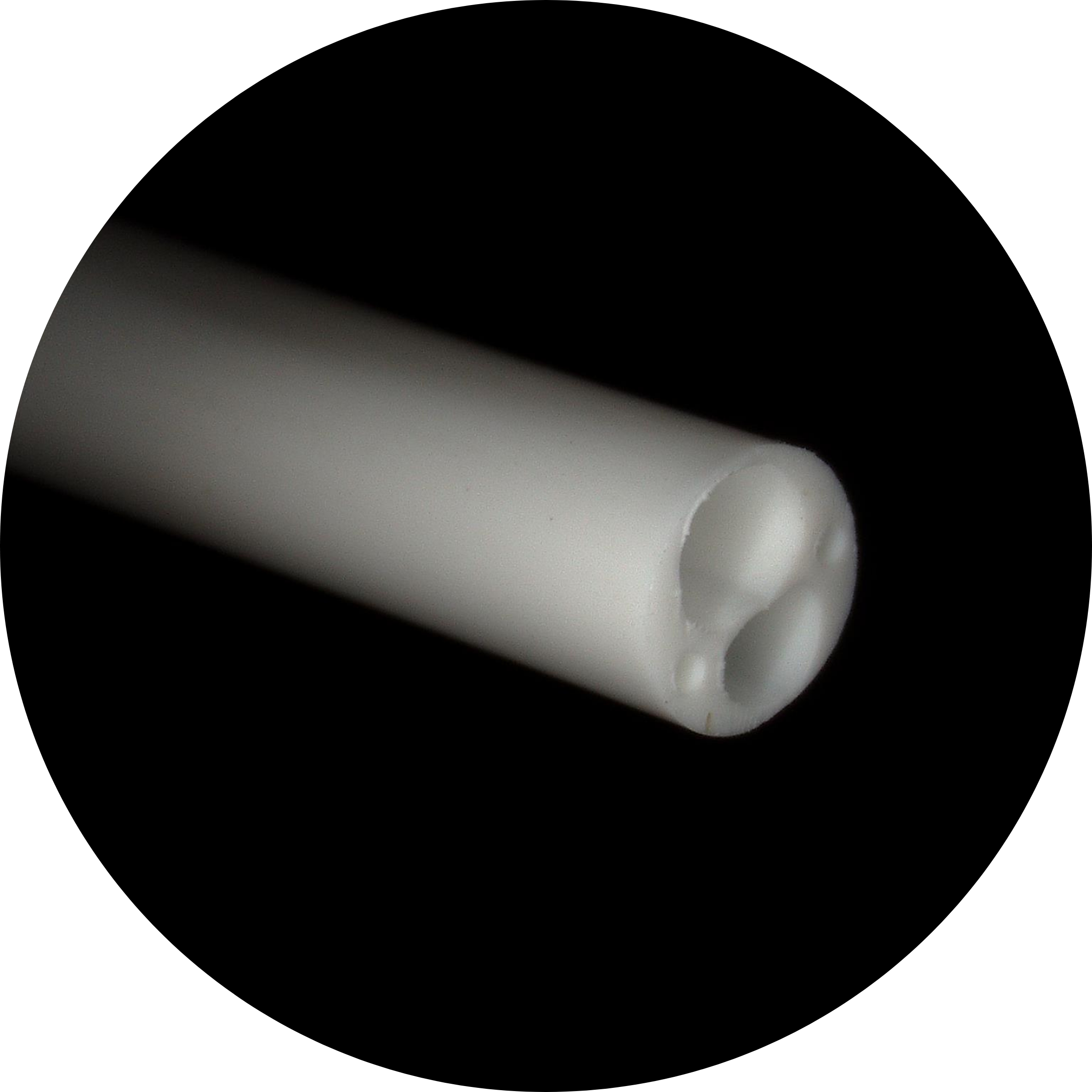

Our capabilities include single- and multi-lumen extrusion, co-extrusion, multi-layer tubing, bump and taper profiles, balloon tubing, and braided or coil-reinforced shafts. We also offer advanced striping options for x-ray visibility and component identification.

All extrusion operations are performed in a controlled cleanroom environment using automated production systems, ensuring the highest levels of quality, repeatability, and performance for your medical tubing needs.

Salt Medical specializes in custom braided and coiled medical tubing designed to improve torque response, flexibility, and kink resistance in advanced catheter systems. Our reinforced shaft solutions are engineered for performance in steerable, delivery, and diagnostic catheters used in minimally invasive procedures.

Leveraging decades of braiding expertise and automated precision equipment, we produce tailored subassemblies or complete outsourced shaft solutions, including:

Tubing can be customized with flat or round stainless-steel wire and polymer monofilaments to meet specific mechanical and flexibility requirements.

Applications: Delivery and guiding catheters, steering mechanisms, high-pressure tubing, kink-resistant sheaths, and stent delivery systems.

Partner with Salt Medical for precision-engineered, reinforced catheter tubing designed for next-generation minimally invasive devices.

Our Tri-Layer Tubing combines three distinct material layers into a single-lumen extrusion to deliver tailored performance for high-pressure and high-precision medical applications. By combining materials like Pebax®, polyamide, polyurethane, EFEP, or custom blends, we achieve enhanced lubricity, tensile strength, and elongation control in one integrated structure.

Features include:

Available in outer diameters from 0.4 mm to 4 mm with tolerances of ±0.015 mm, every extrusion undergoes in-house testing to ensure consistency and reliability.

Salt Medical’s tri-layer tubing supports performance-critical devices where strength, flexibility, and biocompatibility must coexist

Salt Medical’s micro-extrusion capabilities enable the production of ultra-small, high-precision tubing for implantable and minimally invasive medical devices. Using advanced micro-extrusion platforms, we manufacture both silicone and thermoplastic tubing with unmatched control and repeatability.

Capabilities include:

Our cleanroom extrusion environment and automated in-line inspection systems guarantee precision and consistency across every production run.

Applications: Implantable devices, drainage catheters, micro-delivery systems, and other next-generation minimally invasive technologies.

Reliable Tubing for Vascular and High-Pressure Applications

Salt Medical offers high-pressure medical tubing engineered to safely deliver contrast media and fluids under demanding conditions. Our polyurethane tubing, reinforced with polymer monofilaments, maintains constant working pressures of 1200 psi and burst pressures exceeding 1800 psi while retaining flexibility and clarity.

Applications: Vascular delivery systems, high-pressure diagnostic catheters, and infusion devices requiring consistent performance under pressure.

Salt Medical manufactures PEEK tubing for applications demanding high-pressure resistance, chemical stability, and purity. Often used as a lightweight alternative to stainless steel, our PEEK tubing withstands high temperatures, radiation, and harsh chemical environments.

Capabilities:

Applications: Biopharma fluid handling, high-pressure delivery systems, trace analysis of complex fluids, and sterilizable medical tubing.

Our ASTC UV-Shield Tubing safeguards photosensitive drugs and light-sensitive fluids with an opaque outer layer that prevents UV and visible light penetration. This silicone extrusion is tailored for precise ID/OD and packaging requirements.

Applications: Bioprocessing, drug delivery, IVD systems, dialysis, and parenteral nutrition.

At Salt Medical, we specialize in custom medical extrusion designed to meet the precise needs of your device or system. Whether you’re developing steerable catheters, fluid management assemblies, or single-use medical components, our extrusion engineers collaborate closely with you from concept to commercialization.

Our team combines material science expertise, in-house tooling, and automated cleanroom manufacturing to deliver tubing with tight tolerances, complex geometries, and repeatable quality. Every extrusion is customized for performance, biocompatibility, and scalability—so your innovation can move confidently from prototype to production.

Minimally Invasive Catheter Solutions

Fluid Management Systems

Molded and Overmolded Components

Single-Use Assemblies

Advanced extrusion processes create multi-lumen tubing, complex profiles, and high-performance extrusions for critical medical applications.

Use of cutting-edge materials ensures strength, flexibility, and biocompatibility for minimally invasive device manufacturing.

A trusted catheter contract manufacturer in Ireland, delivering reliable solutions for cardiovascular and neurovascular procedures.

At Salt Medical, we combine precision engineering, advanced materials, and cleanroom manufacturing to deliver high-performance medical extrusions you can depend on. From custom designs to high-volume production, our team ensures every tube meets your exact standards for quality, consistency, and performance.