Design & Development for Minimally Invasive Medical Devices

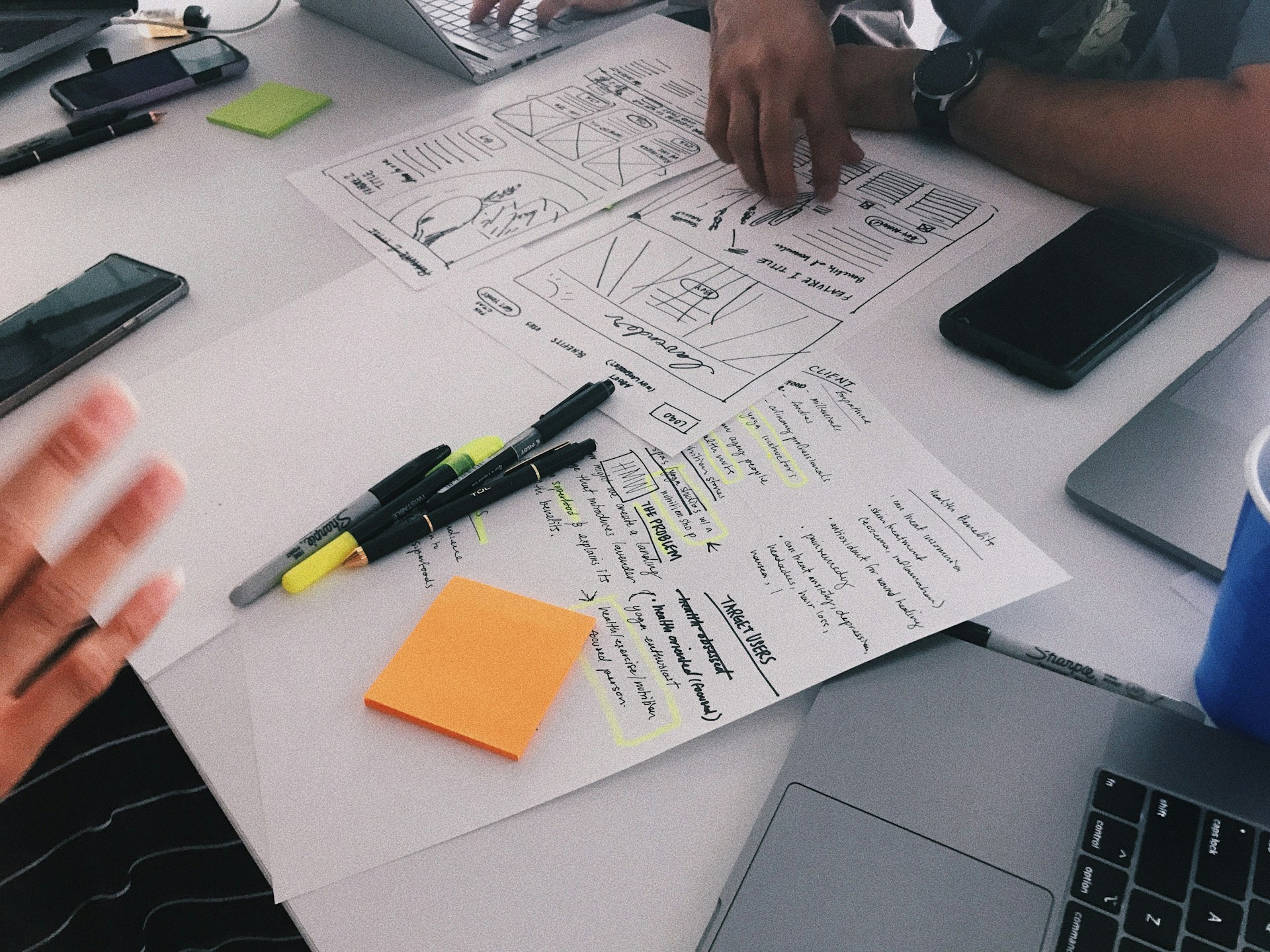

From Concept to Prototype — Bringing Your Innovation to Life with Precision

At Salt Medical, we specialise in transforming early-stage ideas into validated, production-ready prototypes. With deep expertise in minimally invasive devices, we partner with you at every stage, from concept ideation through regulatory-conscious design refinement to prototype realisation.

Why choose salt medical for your design?

From Concept to Reality.

-

Medical-device domain expertise — Our engineers understand the unique challenges of minimally invasive devices (biocompatibility, sterilization, miniaturization, regulatory constraints).

-

End-to-end continuity — Design outputs are optimized for in-house prototyping and downstream manufacturing, minimizing translation losses.

-

Iterative, risk-aware process — We embed risk analyses, design for manufacturability (DfM), and design for regulatory compliance early.

-

State-of-the-art tools & environments — Advanced CAD, multiphysics simulation, rapid prototyping labs, and cleanroom integration.

-

Collaborative, transparent workflow — You stay involved in design decisions via milestones, reviews, and shared access to digital assets.

-

Proven track record — Decades of experience from the team at Salt Medical, delivering medical device programs with quality, speed, and traceability.

Our design & development process

Concept & Feasibility

Preliminary Design

Detail Design & DfM Review

Prototype & Validation

Design Freeze & Handoff

What you get…

Our deliverables

-

Full CAD models and assemblies

-

Engineering drawings & tolerancing

-

Design specification documents & interface control documents

-

Material selections & justification

-

Risk assessment (e.g. FMEA), design validation plan

-

Prototype units (functional, fit/form)

-

Test reports from in-house or subcontracted labs

-

Transition package for prototyping or production

From Design to Prototype – How We Help You Bridge the Gap

At Salt Medical, design development doesn’t end when CAD is complete, we seamlessly transition into prototype realization. Our internal rapid prototyping and partner network ensure your concept is physically tested, validated, and refined before scaling.